Dry ice deflashing and deburring use dry ice particles accelerated by compressed air to remove flash and burrs from plastic and metal parts.

Dry ice deflashing and deburring use dry ice particles accelerated by compressed air to remove flash and burrs from plastic and metal parts.

The polymer polyetheretherketone, more commonly known as PEEK, is becoming increasingly popular within the medical device industry and, in particular, the implantable arena.

The medical device industry sets high standards and tight tolerances on all manufactured products. One specification, and maybe the most important, is surface finish.

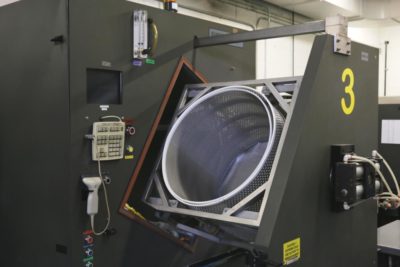

Nitrofreeze® cryogenic deflashing removes flash from glass-filled PEEK coupling rings. This fast, efficient and consistent finishing process uses gaseous nitrogen to freeze the parts and plastic media to break-off surface imperfections and excess material. Because it’s a batch process, cryogenic deflashing eliminates manual deflashing such as hand trimming for faster throughputs and reduced labor costs. […]

Nitrofreeze® cryogenic deflashing removes flash from silicone bumper stops. This fast, consistent and cost-effective process uses gaseous nitrogen to freeze the parts and plastic media to break-off surface imperfections and excess material. Thanks to batch processing, cryogenic deflashing can also reduce lead times and labor costs. The Challenge Nitrofreeze was asked to remove flashing from […]