Dry ice blasting for parts finishing is a non-abrasive process that removes flash and burrs from individual molded or machined parts. Learn about its advantages, and when to use it instead of cyrogenic deflashing and deburring.

Dry ice blasting for parts finishing is a non-abrasive process that removes flash and burrs from individual molded or machined parts. Learn about its advantages, and when to use it instead of cyrogenic deflashing and deburring.

Dry ice deflashing and deburring use dry ice particles accelerated by compressed air to remove flash and burrs from plastic and metal parts.

The polymer polyetheretherketone, more commonly known as PEEK, is becoming increasingly popular within the medical device industry and, in particular, the implantable arena.

The medical device industry sets high standards and tight tolerances on all manufactured products. One specification, and maybe the most important, is surface finish.

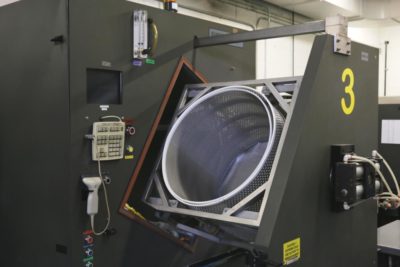

Overview Cryogenic deburring and deflashing systems are versatile by design to meet the wide ranging demands of machined and molded parts. As parts vary in physical properties and geometry, a unique set of processing parameters is required for each part. All new parts submitted for Nitrofreeze Deburring or Deflashing undergo a process development phase known as […]